Deep Learning, Transfer Learning, and Virtual Reality: Digital Levers for Battery Innovation

The BATMAN project includes research activities aimed at developing and studying new digital methods for the simulation and optimization of rechargeable battery manufacturing processes.

These activities are conducted under the leadership of Professor Alejandro A. Franco and his team at LRCS, University of Picardie Jules Verne (Amiens).

Improving the performance of electrochemical cells for energy storage and conversion can be achieved by optimizing their manufacturing processes. However, this can be time-consuming and costly with traditional trial-and-error approaches. Machine learning (ML) models can help overcome these challenges. In academic research labs, manufacturing datasets tend to be small, whereas ML models typically require large amounts of data.

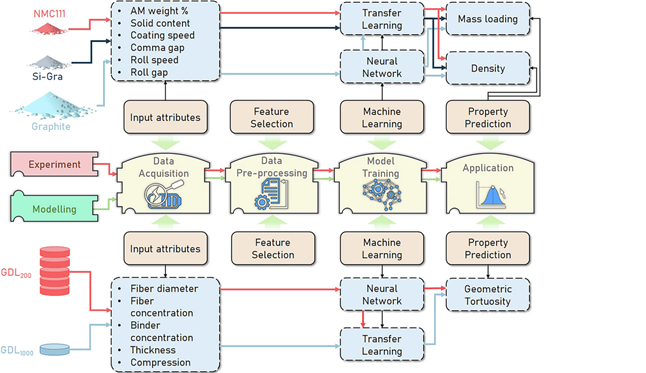

In a recent study, Professor Franco’s team proposed a simple yet innovative application of a transfer learning (TL) approach to address manufacturing problems using a limited amount of data. The team tested this approach with both existing experimental datasets and stochastically generated data. These datasets included component properties (e.g., electrode density) linked to various manufacturing parameters (e.g., solid content, comma gap, coating speed).

They demonstrated the robustness of their TL approach for manufacturing problems by achieving excellent prediction performance for electrodes in lithium-ion batteries and gas diffusion layers in fuel cells.

In the lower part of the diagram, we show the application of the Transfer Learning approach to stochastically generated datasets (GDL200 as the source dataset and GDL1000 as the target dataset) to predict the geometric tortuosity of the gas diffusion layer in fuel cells.

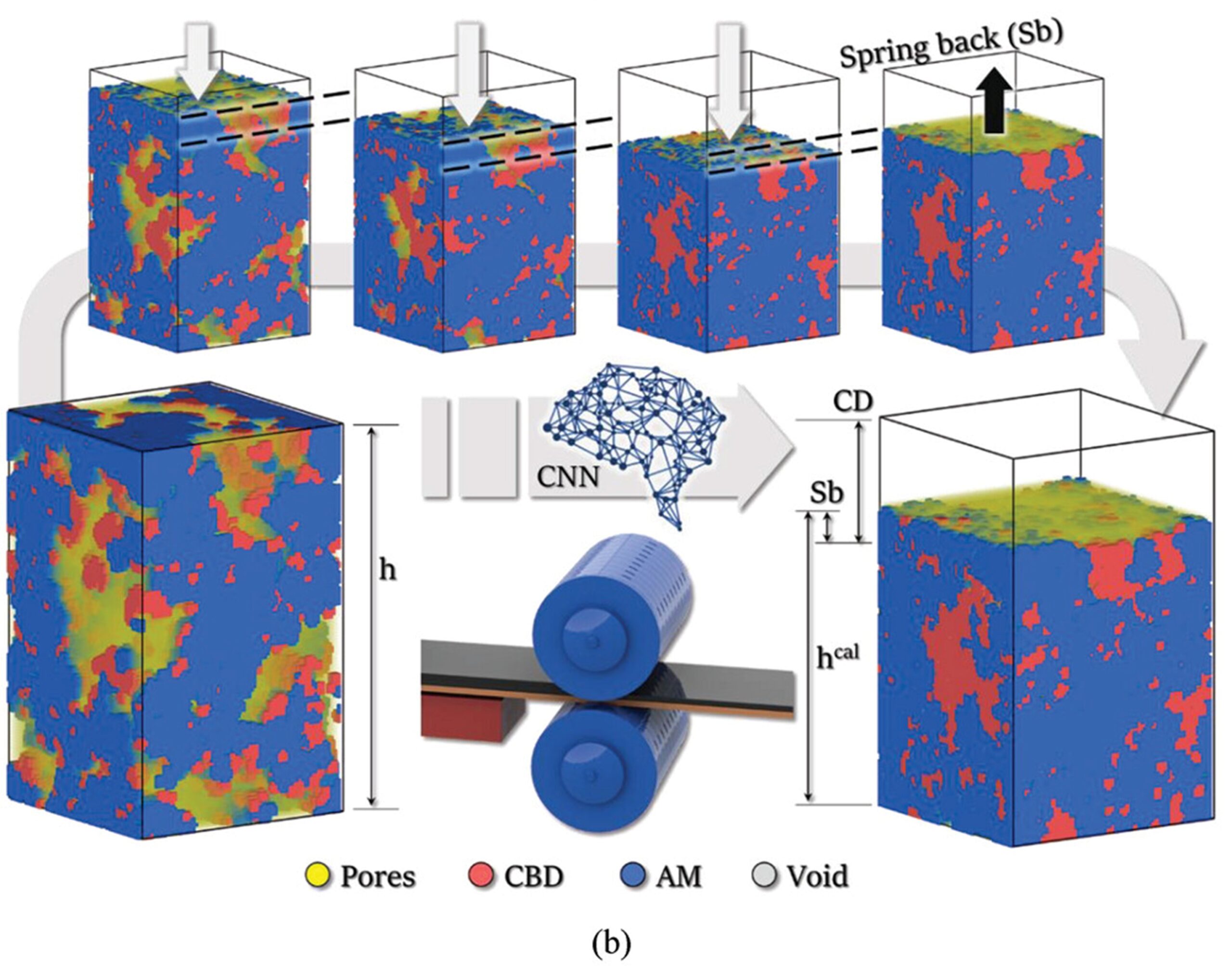

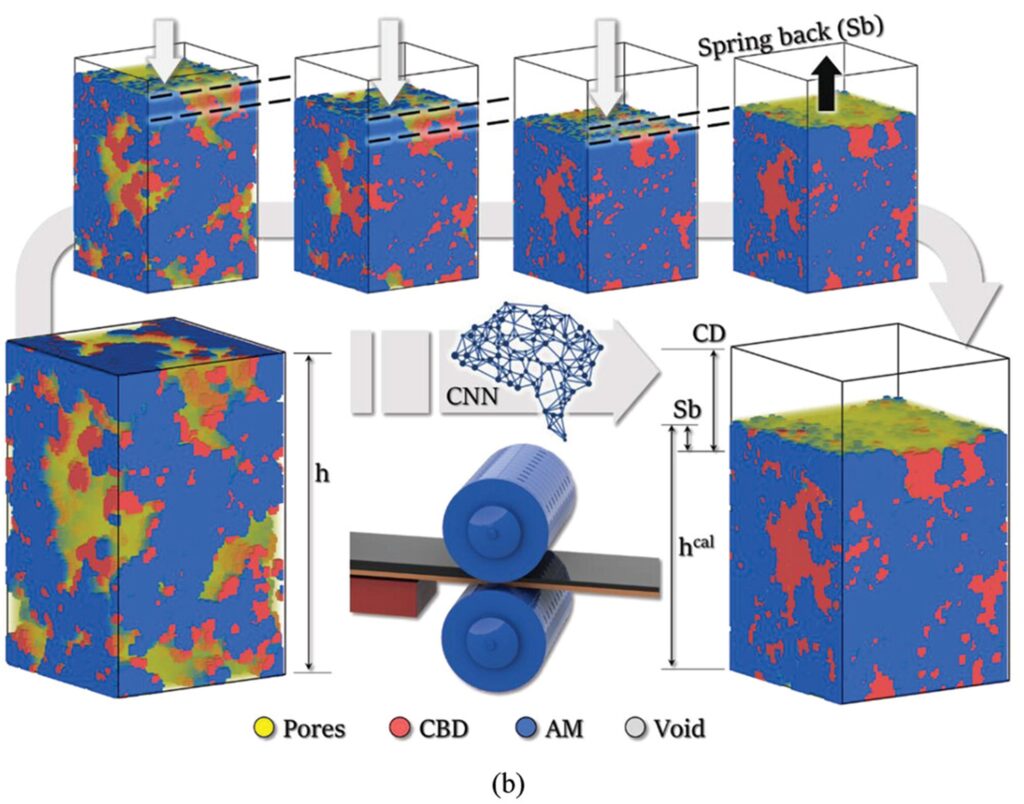

The manufacturing process of lithium-ion battery electrodes directly affects practical cell properties such as performance, durability, and safety. Although physics-based computational modeling has proven to be a very useful method for gaining insights into the interdependencies of manufacturing properties and electrode microstructure formation, its high computational cost prevents its direct use in electrode optimization loops. Professor Franco’s team has proposed a new time-dependent deep learning (DL) model of the lithium-ion battery electrode manufacturing process, demonstrated for the calendaring of nickel-manganese-cobalt (NMC111) electrodes, and trained with time-series data from physics-based Discrete Element Method (DEM) simulations. The DL model predictions were validated by comparing evaluation metrics (e.g., mean squared error and R² coefficient) and functional electrode metrics (contact surface, porosity, diffusivity, and tortuosity factor), showing very good accuracy relative to DEM simulations. Remarkably, the DL model captures the electrode’s elastic recovery during compression (spring-back phenomenon) and the main features of the 3D electrode microstructure without using functional descriptors for training. Furthermore, the DL model’s computational cost is significantly lower than that of DEM simulations, paving the way for near real-time optimization loops of 3D electrode architecture by predicting calendaring conditions required to achieve desired electrode performance.

In a recent study, Professor Franco’s team presented a hybrid physics-assisted machine learning (PAML) model that integrates deep learning (DL) techniques with the Discrete Element Method (DEM) to simulate suspension drying during lithium-ion battery electrode manufacturing. This model predicts the evolution of the microstructure leading to electrode formation as a time series throughout the drying process. The hybrid approach consists of performing a number of DEM simulation steps after each DL model prediction, thereby reducing the risk of non-physical predictions. The PAML model was rigorously tested by evaluating various predicted functional electrode metrics and demonstrated exceptional generalization capability across different formulations. Moreover, integrating DL considerably reduced computation time compared to the original DEM model. These results highlight the potential of combining machine learning methods with traditional simulation techniques to improve efficiency and accuracy in electrode manufacturing.

Additionally, laboratory practices are essential for preparing students and professionals to lead future innovations in energy storage and conversion. However, universities and industries working in the battery field face challenges in providing effective training on the complexities of battery production, mainly due to limited access to battery prototyping facilities or their limited availability for training purposes. Professor Franco’s team has introduced an innovative virtual reality (VR) educational platform called the Battery Manufacturing Metaverse (BMM). BMM promotes accessibility and collaborative learning of lithium-ion battery (LIB) manufacturing through an interactive and flexible VR representation of a LIB pilot production line. It enables collaboration among individuals from different geographical locations. Users can explore electrode and cell chemistries and adjust manufacturing parameters with instructive feedback ranging from cell composition to manufacturing equipment operation. BMM facilitates real-time collaboration using avatars and voice chat. This platform aims to connect students of the Erasmus+ Master’s program on Interdisciplinarity in Materials for Energy Storage and Conversion, enabling seamless knowledge sharing and training. BMM represents a transformative step in battery research and education, offering an immersive and interactive environment without geographical barriers to pave the way for global education and safe training in the energy sector.

- https://www.nature.com/articles/s44334-025-00024-1 ↩︎

- https://advanced.onlinelibrary.wiley.com/doi/full/10.1002/aenm.202400376 ↩︎

- https://doi.org/10.1021/acsami.4c23103 ↩︎

- https://chemistry-europe.onlinelibrary.wiley.com/doi/full/10.1002/batt.202500098 ↩︎

Autres Highlights