COFLUENSS

Coextrusion and fluorination

for optimised all-solid-state sodium-ion batteries

Overview

Co-extrusion and fluorination processes for all-solid-state sodium-ion batteries

Prof. Marc Dubois (ICCF, Université Clermont Auvergne)

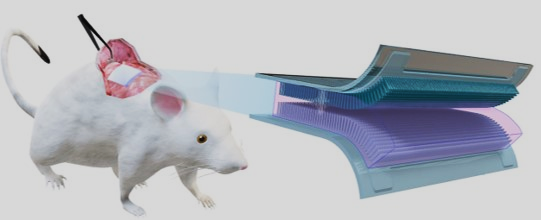

The COFLUENSS project aims to demonstrate the benefits of incorporating fluorine atoms in all-solid-state sodium-ion batteries using extruded polymer electrolytes. The goals include reducing dendrite formation, enhancing interface stability, synthesising new anode and cathode materials, and developing environmentally friendly and scalable processes for (co-)extrusion of next-generation electrolytes and electrodes.

Keywords

Electrochemical storage; all-solid-state sodium-ion batteries; polymer electrolyte; fluorination; co-extrusion

Related news

Pas d’actualités

Tasks

Research activities

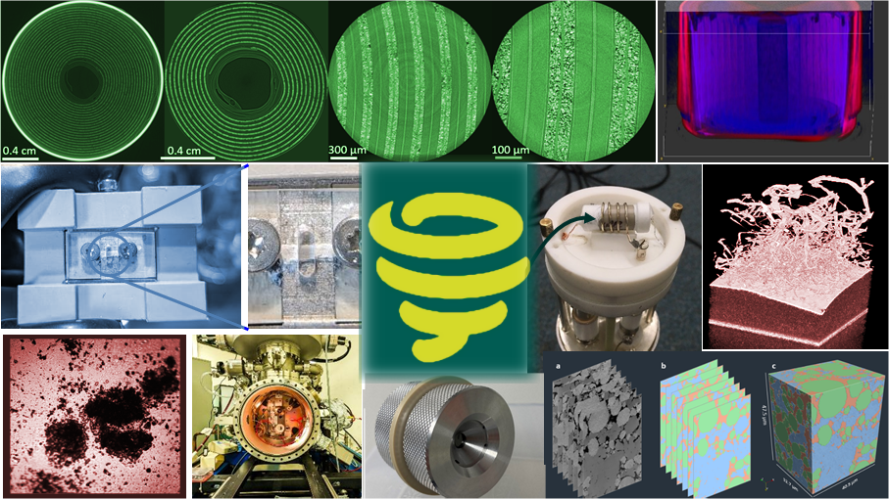

Synthesis of innovative electrode materials suitable for extrusion

Incorporating fluorine atoms on the surface and within the bulk of anode and cathode materials to improve stability and the performance of the cells. This involves applying innovative gas/solid fluorination techniques in order to protect active materials from degradation by and of the electrolyte, and to improve their electrochemical properties. These materials must also withstand the mechanical and thermal stresses during the extrusion process.

Synthesis and preparation of solid electrolytes

The electrolytes, like the electrode materials in this project, must endure deformations and heating during extrusion, while maintaining high ionic conductivity and electrochemical stability.

Extrusion and co-extrusion of the different layers that make up the electrochemical cell

To overcome the limitations of fabrication methods that often rely on toxic and flammable organic solvents, COFLUENSS will explore melt extrusion and co-extrusion techniques. These methods offer a more sustainable approach to battery production by reducing or even eliminating the use of solvents. They also enable simultaneous formation of multiple cell components (electrodes, membranes), improving both manufacturing efficiency and the interfaces between them.

Advanced characterisations

A comprehensive set of characterisation techniques will be employed to better understand sodium storage mechanisms and to optimise interfaces between materials and electrolytes. This approach aims to fill current knowledge gaps and pave the way for the next generation of sodium-ion batteries with improved energy density, safety, and durability.

The consortium

4 academic laboratories

The goal is to define the most effective pathways for fluorination (on surfaces and in bulk) and to make these scalable, while highlighting the key role of fluorine in stabilising and ensuring the safety of all-solid-state sodium batteries. Concurrently, a deeper understanding of side reactions at the material-electrolyte interface is essential to achieve both high sodium storage capacity and high reversibility, and to ensure stability of polymer electrolyte/electrode interfaces. The project aims to quantify performance gains resulting from optimised combinations of anodes/cathodes and to support the development of solid polymer electrolytes.

Also, the benefits of (co-)extrusion as a manufacturing process for solid-state batteries will be demonstrated, alongside efforts to significantly reduce the environmental impact of sodium-ion batteries.

The project emphasises elimination of PFAS in electrolyte formulations, choosing safer and more sustainable alternatives. This is part of the broader goal to develop manufacturing techniques without using solvents, as alternatives to traditional casting methods, which are known for environmental and safety risks (toxicity, fire hazards, long drying steps, residual compounds that can degrade battery performance).

Training of 4 PhD students

Les autres projets PEPR