HIPOBAT

All-solid high-power batteries

Overview

Innovative all-solid high-power sodium-ion and lithium-ion batteries

Dr. Mathieu MORCRETTE UMR LRCS (CNRS – Université de Picardie Jules Verne)

Prof. Martin WINTER Institute of Energy and Climate Research (FZJ)

The goal of this Franco-German project is to develop high-power batteries capable of fast charging and discharging, while maintaining adequate energy density. The research will focus on the rapid diffusion of ions and electrons during charge and discharge, as well as thermal management of the cells. New materials and novel cell designs, along with improved understanding of aging phenomena, combined with advanced characterization and modeling work, will lead to the development of high-performance all-solid batteries based on lithium and sodium. Various applications are targeted in this project: electric vehicles, small portable devices, stationary storage systems, etc.

Keywords

Power batteries, high energy density, all-solid, sodium-ion, lithium-ion, new materials, architecture

Tasks

Research activities

Crystallographic structure work

At the level of crystallographic structures, the work will focus on the synthesis and characterization of lithium and sodium intercalation and conversion materials for positive and negative electrodes, with the objective of improving their ionic and electronic conductivities. New electrolyte materials will also be developed through systematic selection of the most efficient conductive materials, pairing them with compatible polymer matrices, and introducing suitable functional additives. The final stage will be to synthesize materials with optimized composition and morphology at the scale of several hundred grams for the production of the first prototypes.

Electrode structure work

The composition, thickness, porosity, and tortuosity of electrodes will be optimized to find the best trade-off between energy and power. Current collectors will also be improved, and the possibility of adopting an anode-free system (using Li- or Na-based electrolytes) will be evaluated. A balancing of materials at the cell level will help integrate results from the individual component studies and minimize parasitic reactions. In the case of all-solid cells, the benefits of a bipolar format will be examined.

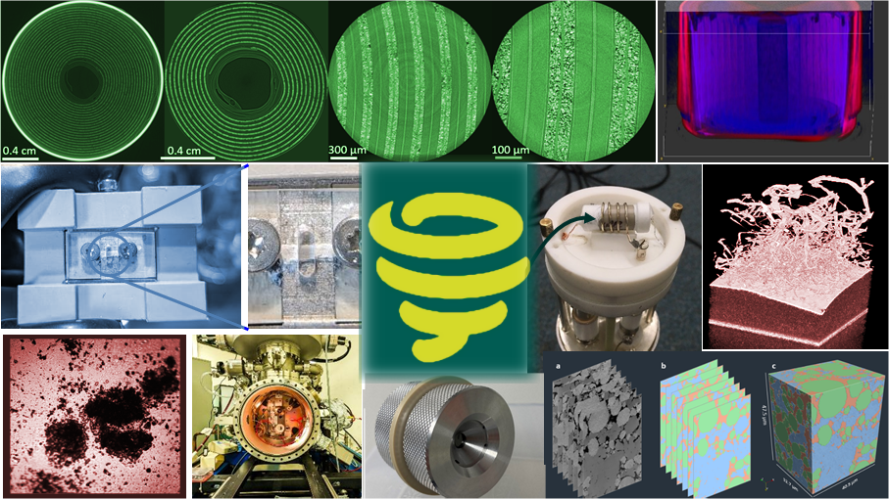

Cell design

Cell design work will be carried out by laboratories experienced in process design compatible with industrial production. Prototypes will be produced on various pilot lines in France and Germany. Multiple cell models with Li- and Na-based electrolytes corresponding to the selected applications will be designed and manufactured. Various manufacturing processes will be evaluated in terms of electrode structure, scalability toward industrial processes, and their economic and ecological impact. At least 20 cells per selected design will be fabricated for tests under different temperature conditions. Because high-power applications require perfect control of battery self-heating, thermal sensors will be installed inside the cells early in the project. The measured data from electrochemical tests will feed into a thermal model and help develop cooling strategies. The final deliverables of this project will include 2 or 3 batteries for portable equipment, integrating the best results from studies at multiple scales.

Cell performance

The specific electrical, thermal, and lifetime properties of the produced high-power cells will be measured and compared with state-of-the-art ones. Tests will be performed at lab scale using selected key performance indicators. Special attention will be given to studying the relationship between fast charging and aging. These tests will feed into an electro-thermal aging model usable for BMS algorithms and for system definition in storage.

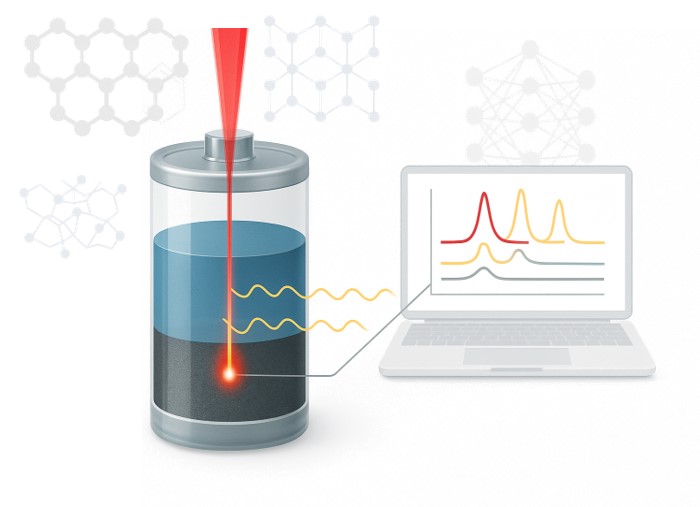

Characterization and modeling

Characterization and modeling work will be carried out in parallel with the four tasks above to improve their efficiency and scope. Advanced characterization (notably tomography, in-situ techniques, post-mortem analysis) will help understand battery functioning in greater detail—especially lithium transport within pores and degradation of electrode/electrolyte interfaces caused by parasitic reactions under fast charging. In situ and operando techniques already used in several labs in the consortium will be adapted to fast-charging batteries. Multiscale multiphysics modeling will be developed from the microscopic to the macroscopic scale. A thermal model will help manage self-heating risk for high-power batteries.

The consortium

France: 6 academic laboratories, Germany: 6 laboratories

This project will allow significant advances in high-power batteries with adequate energy density. New electrode and electrolyte materials for all-solid Li and Na power batteries will be optimized, along with cell architectures for different target applications. Transferability to industrial production will be a key focus, and first prototypes of portable equipment batteries will be fabricated before the end of the project. In parallel, multiscale multiphysics models will be available to help future designers select optimal structures for specific applications. The holistic testing approach will enable parameterization of an electro-thermal aging model usable for BMS algorithms and system design. Battery management functions—such as various state indicators (state of charge, health, power state, energy state)—will be developed for both Li and Na batteries to allow safe operation of these cells.

High-power batteries have an important role in deploying electric vehicle fleets with short charging times. They are also essential for grid stabilization, in a context where increasing reliance on renewable energies—often intermittent—is unavoidable. Environmental considerations will be addressed especially by comparing sodium vs. lithium technologies, developing anode-free cells that require fewer materials and offer better recyclability, and using eco-friendly manufacturing processes.

Training of 9 PhD students and 10 postdoctoral researchers in the French academic laboratories

Les autres projets PEPR