SCAR

Battery safety and end-of-life dismantling

Overview

Optimized battery system design for an automated, safe, and sustainable dismantling process

Dr Hélène PORTHAULT (CEA-Liten Institute)

The creation of a battery recycling sector aims to reduce the carbon footprint and tensions over certain materials. Over the past 20 years, battery energy has multiplied by 5, increasing risks for recyclers given rising throughput. SCAR proposes to intervene as early as the design phase to facilitate dismantling and enhance safety. It relies on a digital twin to automate disassembly and optimize battery design, coupled with a deep-discharge feature. The project also develops robotic dismantling techniques with intuitive programming, making disassembly scenarios safer and more adaptable. The whole will be evaluated through life cycle and cost analyses, integrating performance criteria and scale-up.

Keywords

Battery system; safety; eco-design; dismantling; automation; digital twin; recycling; impact assessment

Related news

Pas d’actualités

Tasks

Our research

Project framework definition

This first task will define the boundaries of the study (choices of formats, chemistries, etc.). A risk analysis will then be carried out to identify risk levels during dismantling phases and to target critical phases for automation. Evaluation criteria for life cycle and cost analyses will also be defined (recycling rate, disassembly time, etc.), together with interviews with industry actors to best define the important criteria and various scaling scenarios.

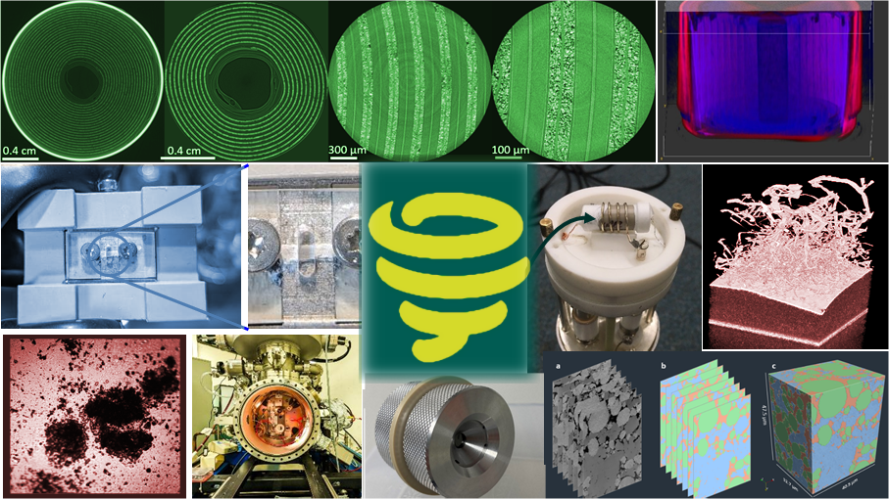

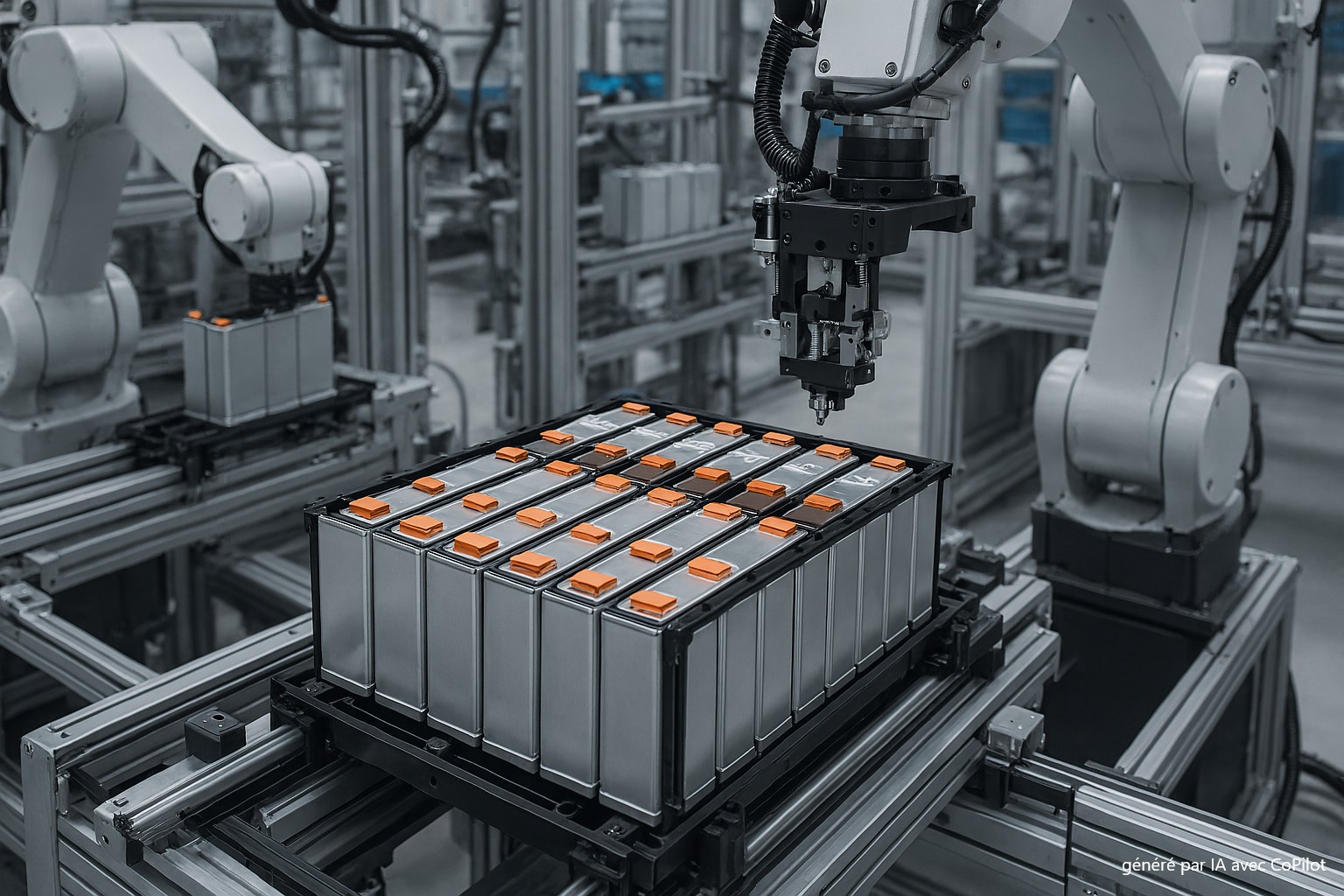

Automated dismantling: Innovative robotic functionalities & eco-design

Based on earlier choices, a digital twin of the battery system will be created to accelerate research and development. It will serve as the basis for design iterations aimed at facilitating automated dismantling by developing innovative robotic functions. This work will also include the development of an intuitive programming interface to allow use by operators who are not robotics experts. These innovations will be evaluated via life cycle and cost analyses to ensure their techno-economic relevance with scale-up in mind.

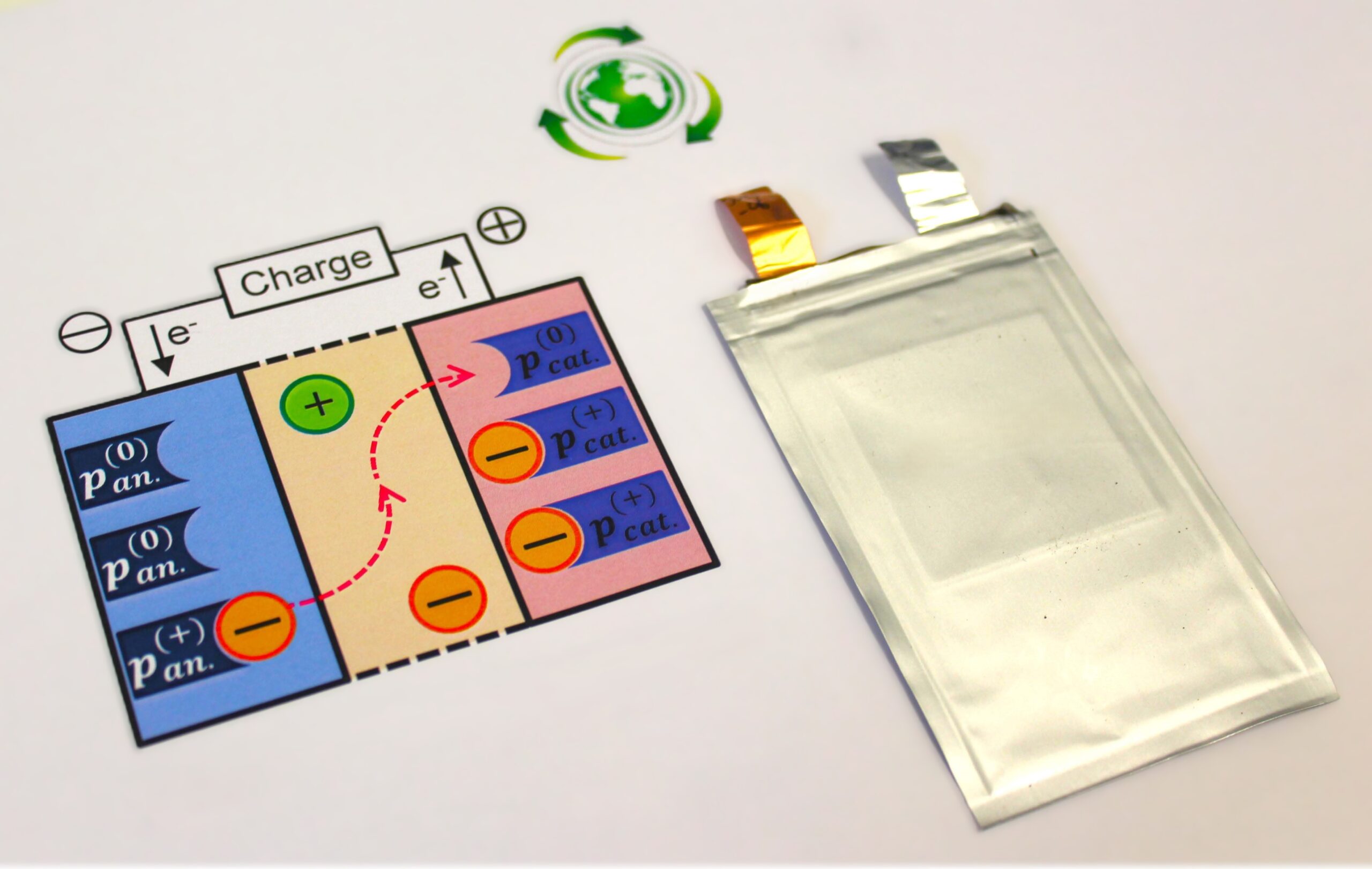

Deep discharge at end of life

A deep discharge module, integrated from the battery’s design phase, will be developed with the goal of performing final discharge during idle periods at end of life (storage, transport, etc.). It will be developed at different scales: cell, module, and pack. The validity of the proposed solution will be demonstrated via stress tests on a system at 0% state of charge (SOC) and deep discharge. A life cycle and cost analysis will also be conducted to ensure the technical solutions proposed are appropriate.

Pack/module scale demonstration & final evaluation

A demonstrator at pack/module scale, incorporating real cells, will be designed to carry out a full-scale demonstration of the various innovations developed during the project (automation, discharge, etc.) using robots already available at partner institutions. The final life cycle and cost assessment will be made based on these results. The designs and solutions developed during SCAR will be presented to a selected group of industrial actors (recyclers, battery manufacturers, etc.) to gather their feedback and recommendations on the proposed innovations.

Consortium

1 academic laboratory and 2 CEA institutes

The collaborative work in SCAR will bring together scientists from very different fields (batteries, robotics, eco-design), thus accelerating developments on very complex subjects such as automated dismantling. The joint development of new robotics modules (grippers and software) will unlock new functionalities (cable disconnection, de-soldering, etc.), opening the way to new levels of dismantling. The innovative solution of an internal discharge module integrated from the design phase will also enable new processing pathways. Life cycle and cost analyses will help better identify key and/or penalizing steps so as to direct R&D efforts while ensuring a final technical solution that is relevant.

SCAR will help develop a robust foundation to facilitate the development of a European recycling sector. Securing batteries could enable avoiding destructive steps like pyrometallurgy or shredding and allow access to higher-quality and more easily sortable materials. Recycling could become more efficient (higher recycling rates, fewer sorting and purification stages, lower costs, etc.), facilitating closed-loop reintegration or enabling the recycling of systems that are harder to make profitable, such as LiFePO₄ batteries, for example.

Training 1 PhD student and 3 postdoctoral researchers

Les autres projets PEPR